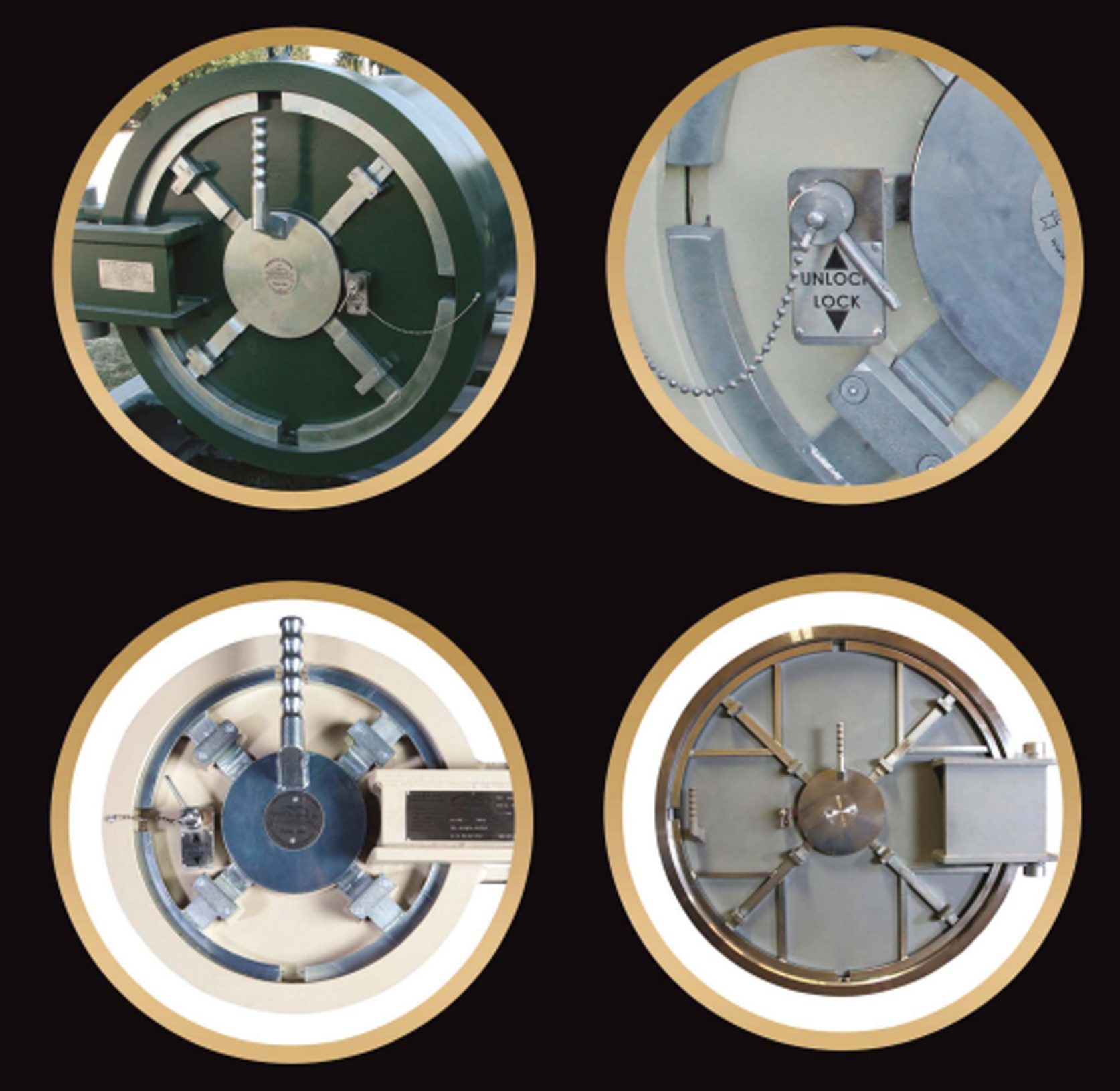

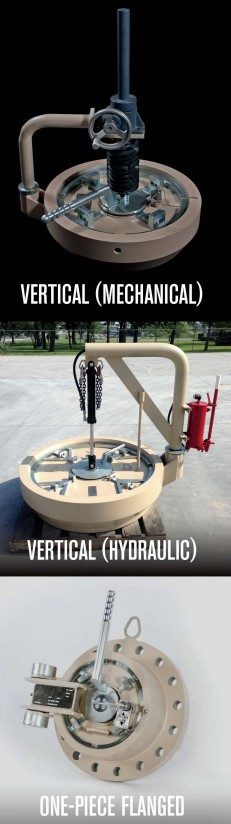

Quick Opening

Pipeline Equipment, Inc. has designed and developed a quick opening closure. This innovative, patented closure system is safe and easy to operate and may be used in a broad range of applications. With more than 15 years of engineering, design and machining experience Pipeline Equipment, Inc. provides closures to meet customer specifications and achieve quick deliveries.

Easy To Operate

Operation of the closure can be accomplished by one person without the use of tools. The integration of the locking segments, locking mechanism and door handle into the door provides a compact and efficient design. To open the door, the handle requires only a quarter turn, which moves the locking segments from their stowed position. The internal components of the locking mechanism are protected by a weather seal and are stainless or plated to protect them from rust and corrosion. The o-ring groove is machined into the door with the hub o-ring seat area recessed to protect the seat during pig launching and receiving. This configuration assures a positive seal when the door is closed and locked.

Integrated Twin Locks

The safe operation of the closure is ensured by a redundant design in which the closure cannot be opened without the removal of the pressure alert valve and the movement of the safety lock. The pressure alert valve also provides the operator an indication of the presence of any residual pressure in the vessel should the operator inadvertently attempt to open the closure prior to all pressure on the vessel being relieved. Additionally, the safety lock mechanism prevents the door handle from being moved to the open position until after the pressure alert valve has been safely removed. The safety lock must also be returned to the locked position in order for the pressure alert valve to be installed.